General Information

C55 is a carbon steel for general purposes found in three variants in EN ISO 683-1.

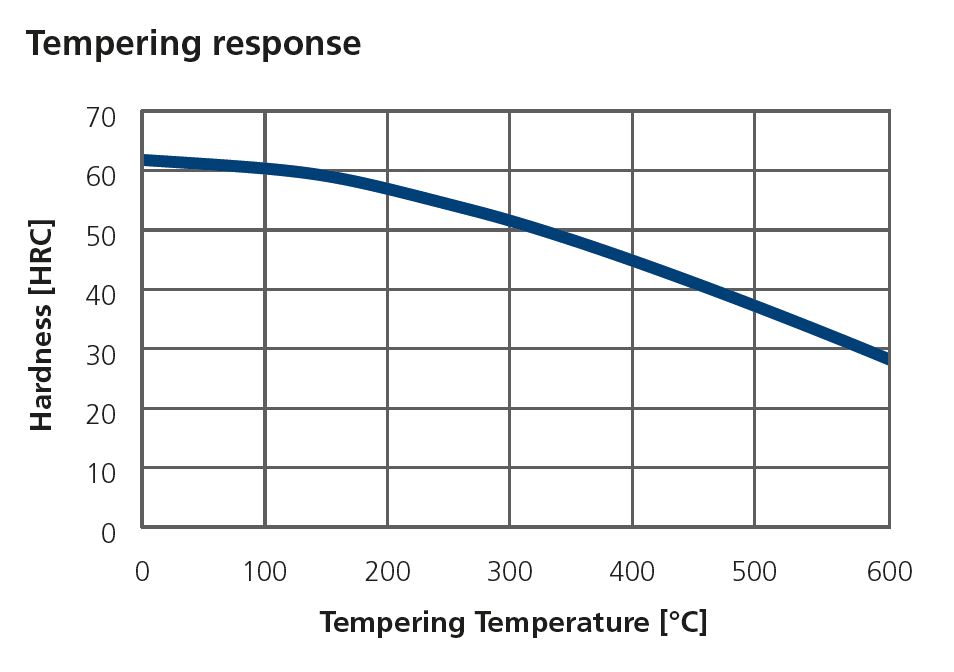

510A is an ingot casted steel. High hardness (approx. 60HRC) and high strength can be achieved after hardening due to the relatively high carbon content. The steel is suitable for various type of applications where high strength is needed

056K is a low alloyed steel for quench and tempering. Used for machine parts etc. Can be induction or flame hardened

8665 is a continuous casted variant meeting all three of the EN ISO standards.

For additional Heat Treatment Data, please visit the Heat Treatment Guide.

Similar designations

C54, C55E - 1.1203, C55R - 1.1209, 070M55 (BS970), ASTM/SAE 1055, SS 1655, C55R, Cf53, 1.1213