General Information

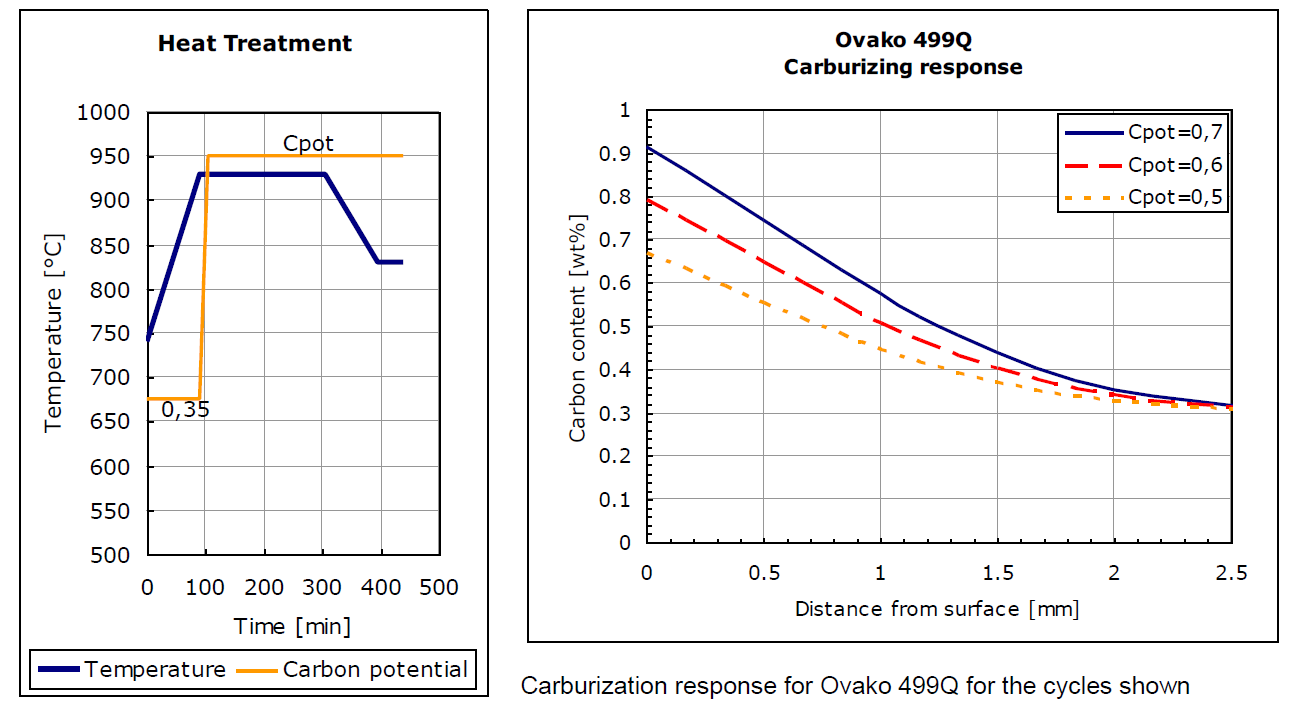

Ovako 499Q is a tool steel suitable for carburizing or used in quenched and tempered condition. The alloying strategy gives a high tempering resistance which make the steel suitable for using in elevated temperature applications. Ovako 499Q is produced through the Ovako IQ-process (isotropic quality) to a cleanliness comparable to VAR-remelted quality. Carburizing requires certain precautions due to the high alloying content. A low carbon po-tential should be used and pre-oxidation is recommended to enhance carbon diffusion. The strong carbide formers will give an excellent microstructural stability and excellent wear properties.

* Designation followed by "*" is not an official EN standard grade but named according to the rules in EN 10027.

IQ-Steel®

IQ-Steel® is an isotropic quality ultra clean steel optimized for high fatigue strength under multi axial loading.

Other properties (typical values)

| Youngs module (GPa) | Poisson´s ratio (-) | Shear module (GPa) | Density (kg/m3) |

|---|

| 210 |

0.3 |

80 |

7800 |

| Average CTE 20-300°C (µm/m°K) | Specific heat capacity 50/100°C (J/kg°K) | Thermal conductivity Ambient temperature (W/m°K) | Electrical resistivityAmbient temperature (µΩm) |

|---|

| 12 |

460 - 480 |

40 - 45 |

0.20 - 0.25 |

Disclaimer

The information in this document is for illustrative purposes only. The data and examples are only general recommendations and not a warranty or a guarantee. The suitability of a product for a specific application can be confirmed only by Ovako once given the actual conditions.The purchaser of an Ovako product has the responsibility to ascertain and control the applicability of the products before using them. Continuous development may necessitate changes in technical data without notice. This document is only valid for Ovako material. Other material, covering the same international specifications, does not necessarily comply with the properties presented in this document.