General Information

22NiCrMo12-5* is a group of carburizing steel with high hardenability. High strength combined with excellent toughness and high fatigue strength makes them well suited for applications in the mining industry. Tight alloying windows provides the grades with excellent hardenability and strength control. Can be delivered as rolled, annealed or austenitized and air hardened.

253A - Standard variant with high hardenability and controlled sulphur content for improved machinability.

253R - Variant with reduced sulphur content to meet the clean steel BQ (Bearing Quality) requirement for improved fatigue properties.

253L - Variant with increased carbon range for increased core hardness after carburizing. Controlled sulphur content for improved machinability.

253S - Variant with slightly increased carbon range for increased core hardness after carburizing. Controlled sulphur content for improved machinability.

4722 - Continous cast variant with slightly increased carbon range for increased hardness after carburizing.

BQ-Steel®

BQ-steel® is a bearing quality clean steel optimized for fatigue strength and is also ideal for new design solutions outside the bearing industry.

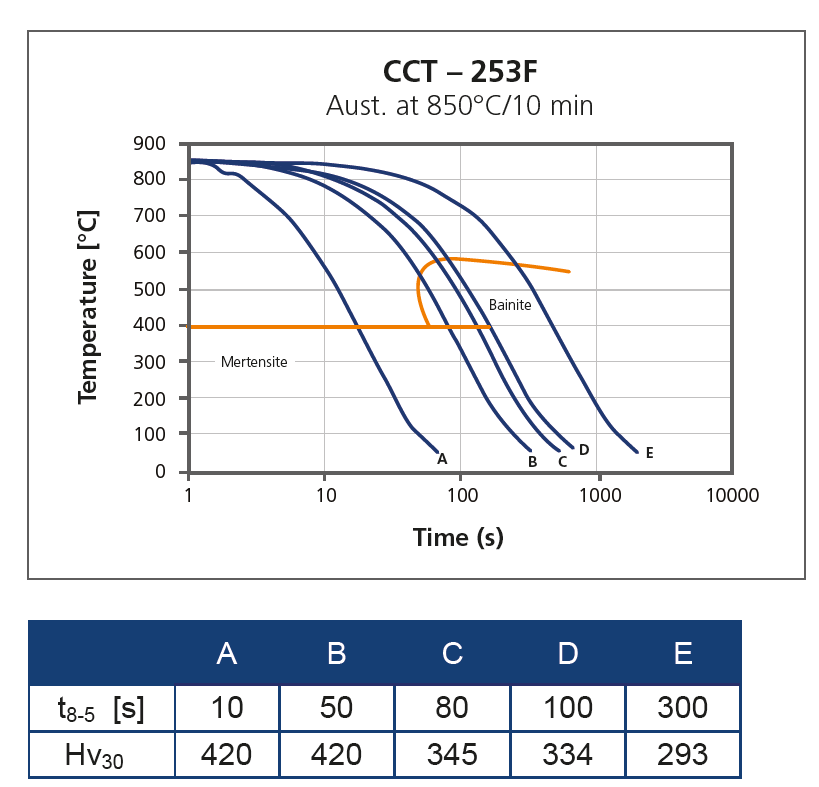

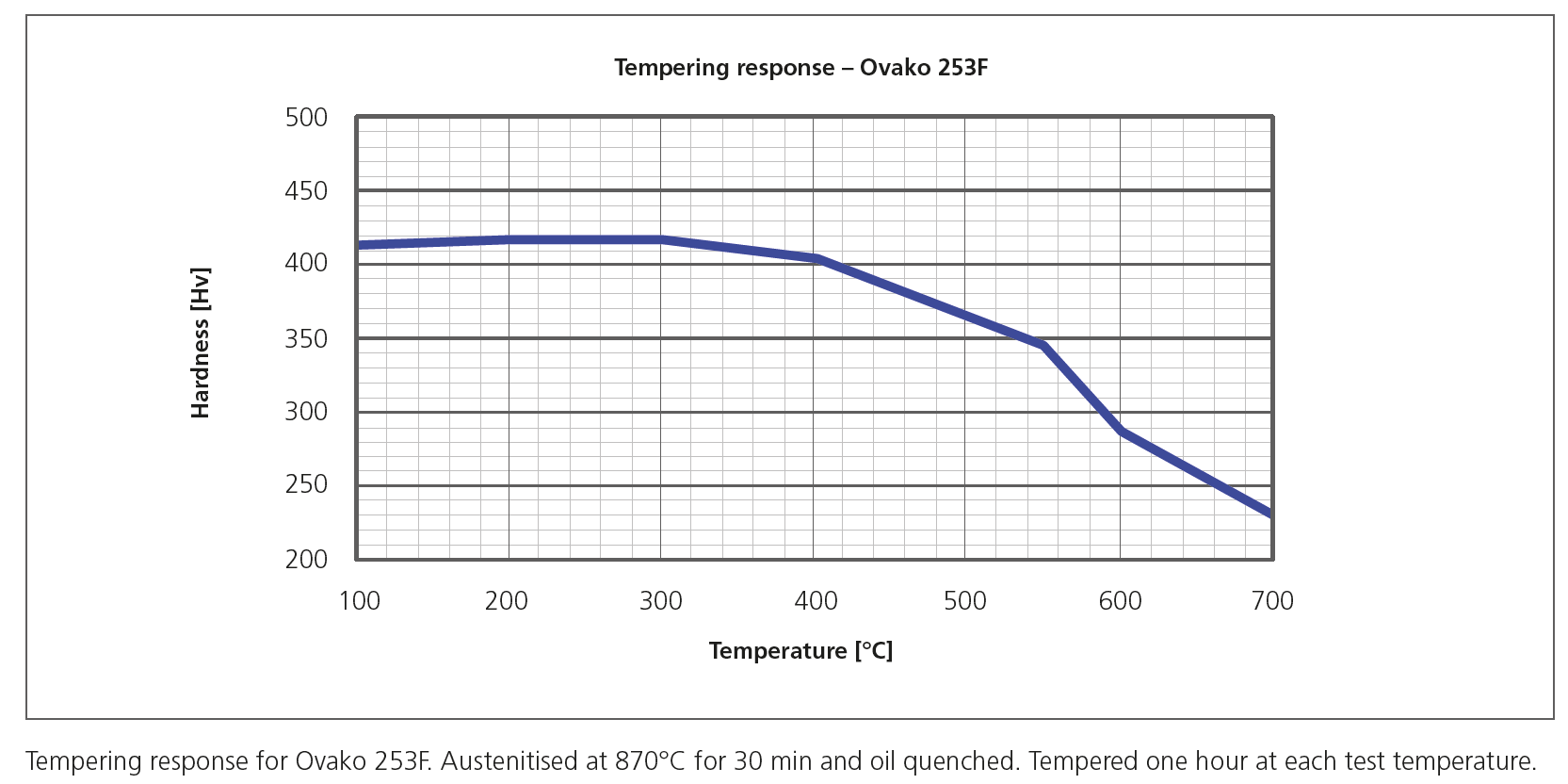

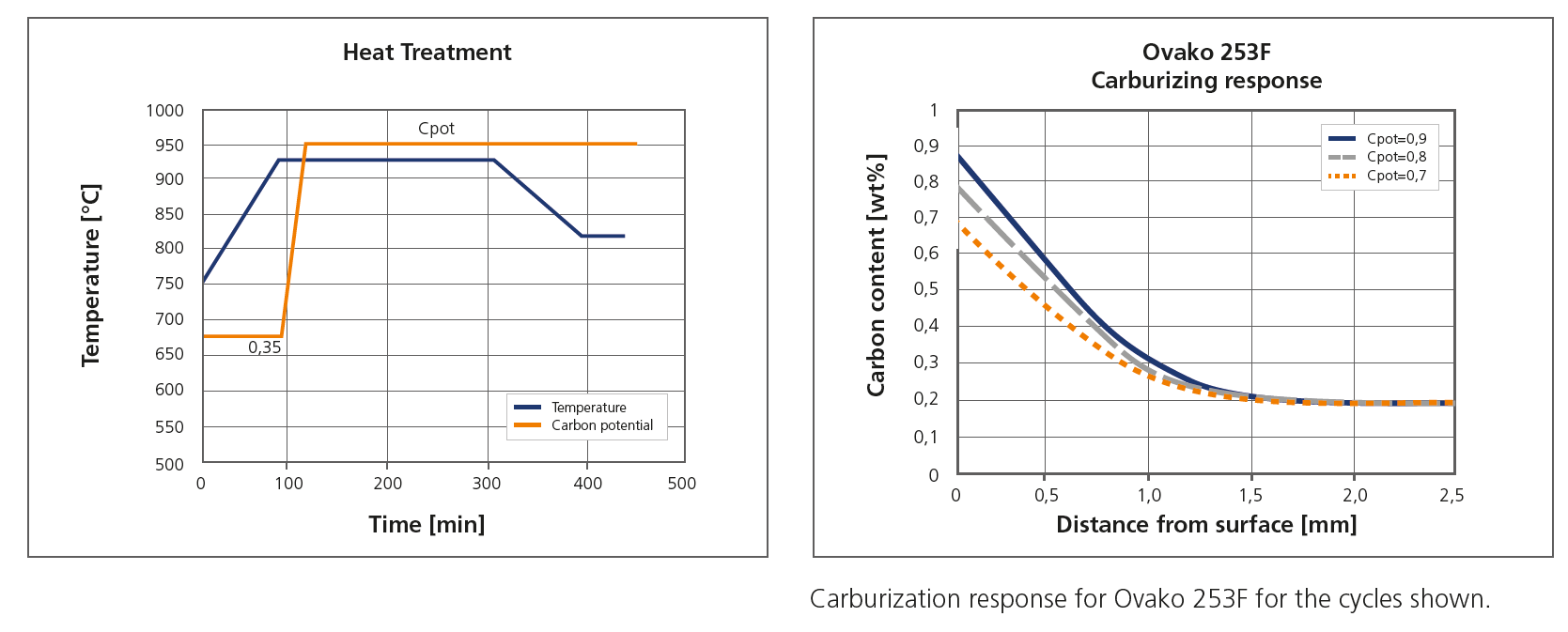

For additional Heat Treatment Data, please visit the Heat Treatment Guide.

* Designation followed by "*" is not an official EN standard grade but named according to the rules in EN 10027.

Similar designations

9317, 14NiCrMo13-4, 23NiCrMo12-5, 25NiCrMo12-5, 19NiCrMo11-5, EN27