General Information

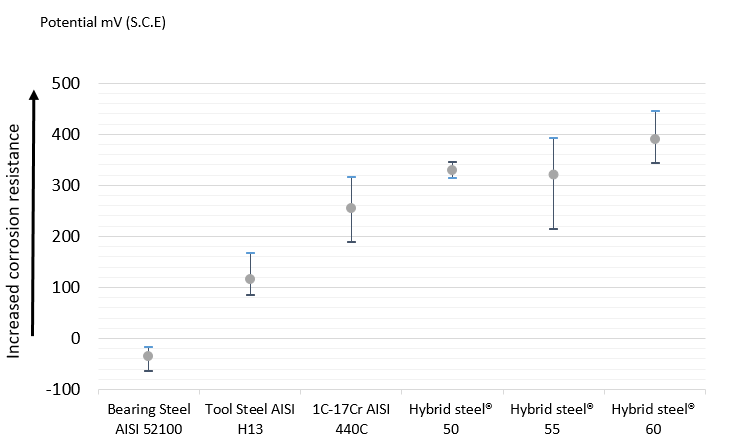

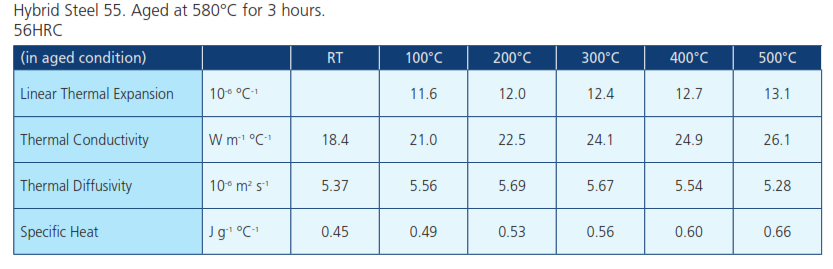

Hybrid Steel® is a low carbon steel containing a number of carefully controlled alloying elements, most importantly nickel, chromium, aluminium, molybdenum and vanadium. These enable it to develop its full properties after aging at elevated temperature (500–620°C). The chromium and aluminium content also improves corrosion resistance. The variant 197A is offered under the name Hybrid Steel 50 and the variant 297A is offered under the name Hybrid Steel 55 and the variant 397A is offered under the name Hybrid Steel 60.

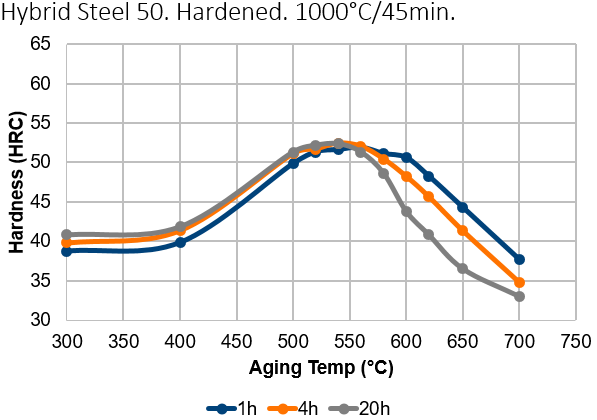

Hybrid Steel 50 - Engineering steel.

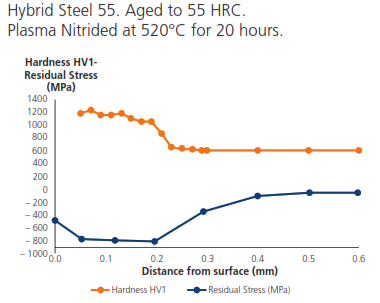

Hybrid Steel 55 - Engineering steel.

Hybrid Steel 60 - Bearing steel.

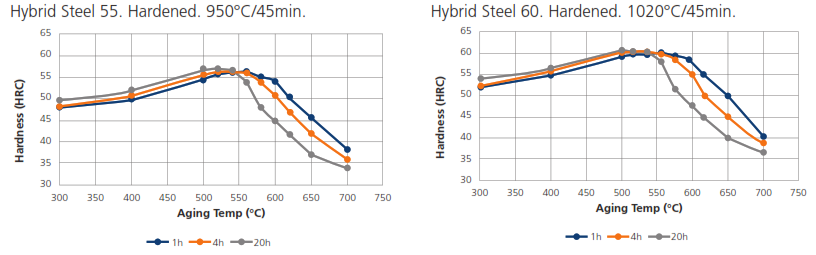

Maximum hardess after aging: Hybrid Steel 50, 50HRC. Hybrid Steel 55, 55HRC. Hybrid Steel 60, 60HRC.

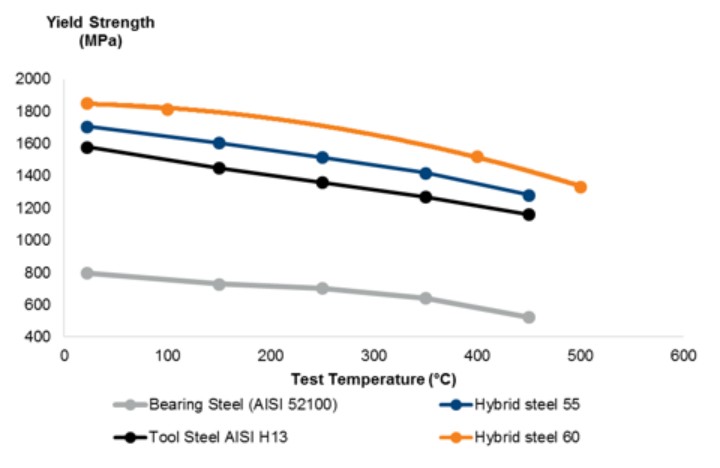

Hybrid Steel offers superior mechanical and fatigue strength compared to conventional steel grades at elevated temperatures.

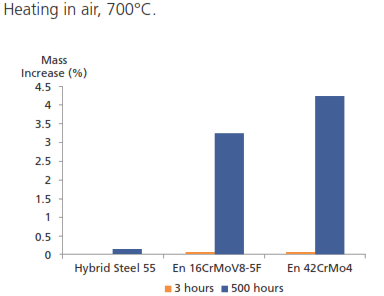

- Excellent elevated temperature strength

- Flexible hardness, achieved by an aging treatment in the temperature range 500–620°C

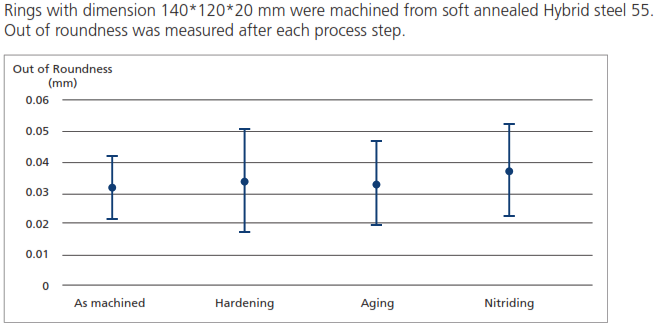

- Extremely good dimensional stability when aging is applied

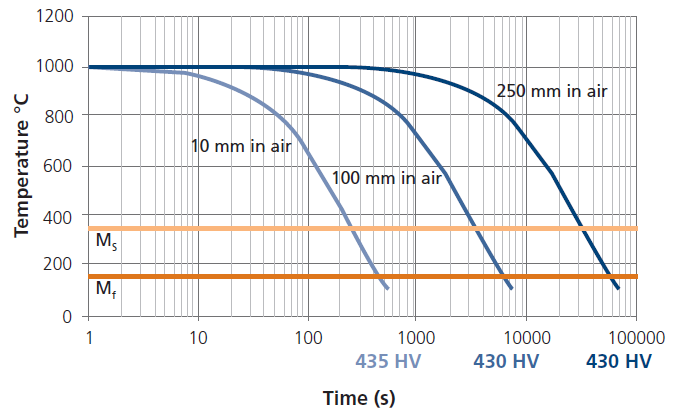

- High uniformity of properties also for large components

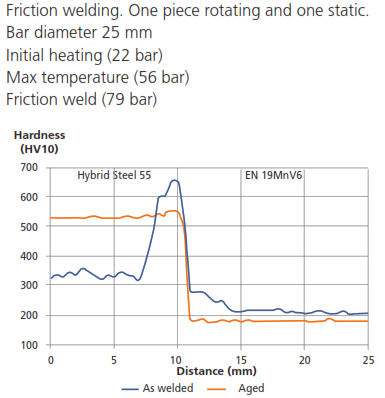

- Good weldability, no preheating necessary

- Corrosion resistance comparable to AISI 440C

The density for these grades is 7582 kg/m3.

* Designation followed by "*" is not an official EN standard grade but named according to the rules in EN 10027.

Similar designations

X20NiCrAlMoV6-5-2-1, X30NiCrAlMoV6-5-2-1 , Ovako197A, Ovako297A, Ovako397A