General Information

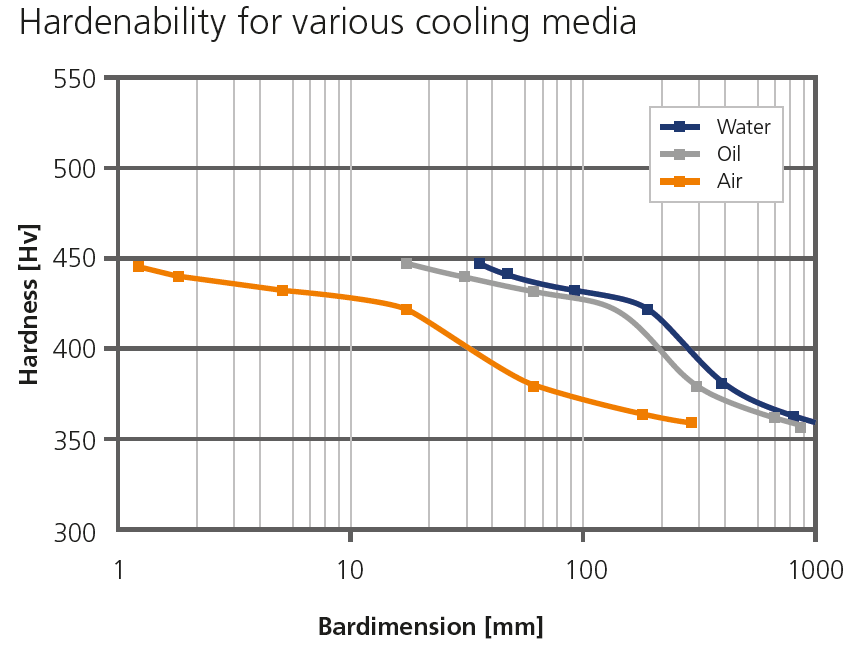

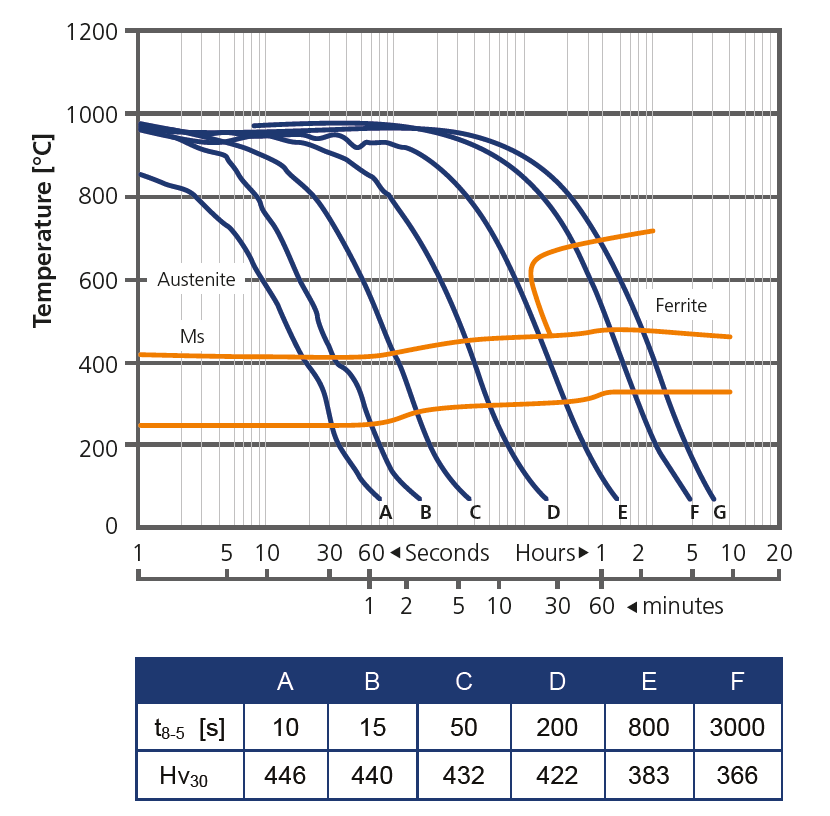

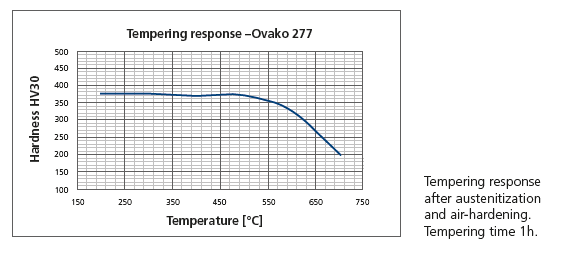

Ovako 277 is an air hardenable steel that is suitable for case hardening, nitriding or quench and tempering. By using air-hardening or gas quenching it is possible to reduce the amount of quenching distortion. Additionally the use of quenching medias such as oil and salt can be avoided, which improves both safety and environment. It is produced in two quality classes.

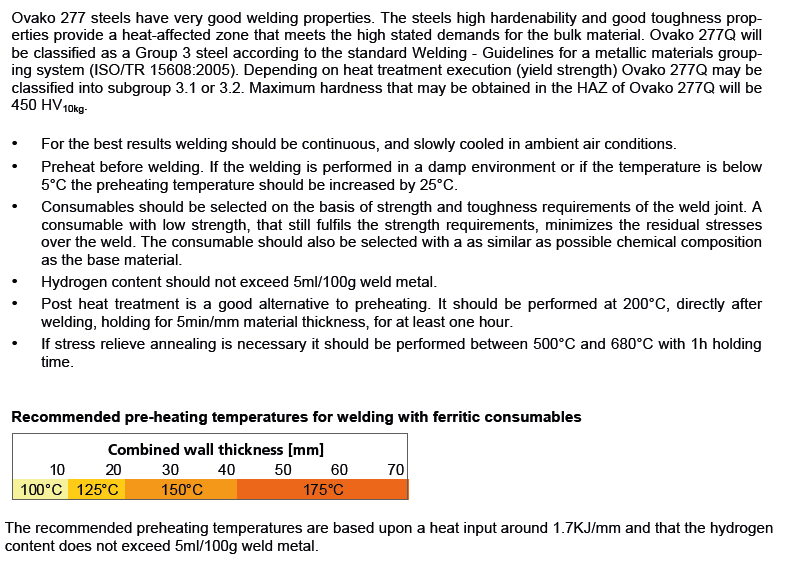

Ovako 277 steels has very good welding properties. The steels high hardenability and good toughness properties provide a heat-affected zone that meets the high stated demands for the bulk material. Ovako 277Q will be classified as a Group 3 steel according to the standard Welding - Guidelines for a metallic materials grouping system (ISO/TR 15608:2005). Depending on heat treatment execution (yield strength) Ovako 277Q may be classified into subgroup 3.1 or 3.2. Maximum hardness that may be obtained in the HAZ of Ovako 277Q will be 450 HV10kg.

277L - Variant with regulated sulphur content for optimized machinability.

277Q - IQ Isotropic Quality for improved properties transverse to the rolling direction and better fatigue strength due to higher cleanliness level with a finer size distribution of non-metallic inclusions. The steel grade is made according to new process that modifies the the inclusion morphology, i.e. a lower number of elongated sulfides and reduced size distribution of oxides, both in avarage and in the spread. By using air hardenig or gas quenching it is feasible to reduce the amount of queching distorsion.

* Designation followed by "*" is not an official EN standard grade but named according to the rules in EN 10027.

IQ-Steel®

IQ-Steel® is an isotropic quality ultra clean steel optimized for high fatigue strength under multi axial loading.

Similar designations

16CrMoV8-5, 16CrMoV8-5*