General Information

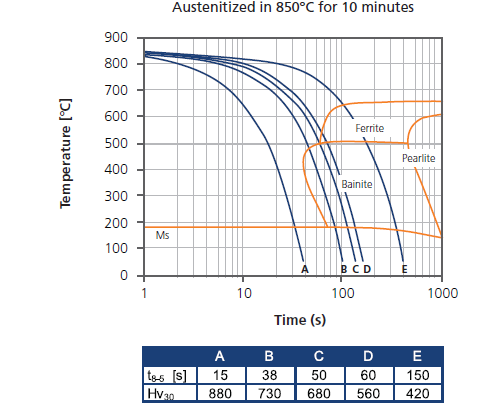

Ovako 824 is a through hardening bearing steels intended for rolling contact and other high fatigued applications. In the hardened condition the high hardness, high strength and high cleanliness provides the steel with the right properties to withstand high cycle, high stress fatigue. Ovako 824 is mainly used for small and medium sized bearing components. It is also regularly used for other machine components that require high tensile strength and high hardness. The hardenability approximately corresponds to a ring with maximum 20 mm wall thickness. It is suitable for both martensitic and bainitic hardening. Ovako 824 comes in two variants. One Bearing Quality (BQ) variant that fulfills tough Ovako internal quality demands and consequently also the ISO 683-17 demands. One Isotropic Quality (IQ) with higher demands regarding micro inclusion cleanliness and improved isotropic properties. Additionally this variant has a slightly reduced carbon content to reduce the carbide segregation tendency. The IQ variant is especially suited for applications subjected to a complex loading mode.

824B - Bearing quality (BQ) variant

824P - Bearing quality (BQ) variant with low sulphur content

824Q - Isotropic quality (IQ) variant

IQ-Steel®

IQ-Steel® is an isotropic quality ultra clean steel optimized for high fatigue strength under multi axial loading.

BQ-Steel®

BQ-Steel® is a bearing quality clean steel optimized for fatigue strength and is also ideal for new design solutions outside the bearing industry.

Similar designations

100CD7, ASTM A485 grade 3, 1.3537