About Piston Rod Predictor

Piston Rod Predictor

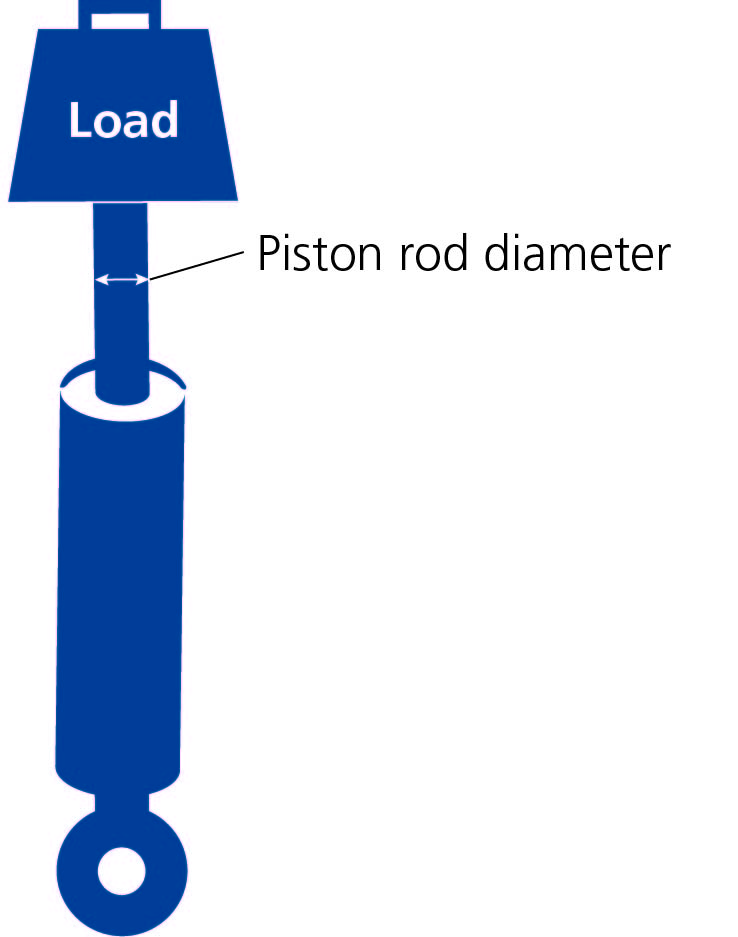

Piston Rod Predictor is a tool developed to help you compare the resistance of different steel grades to buckling in piston rod applications. Most hydraulic cylinders are loaded in axial compression and therefore dimensioned against fail by buckling. Higher strength steel gives better resistance to buckling and also offers the possibility to downsize piston rods, helping to reduce both weight and cost. Ovako manufactures a range of hard-chrome-plated or Nickel-chrome-plated ready-to-use bars and tubes, known as Cromax®. In our piston rod predictor, you can compare Cromax steel grades with the most commonly used standard grades for piston rod applications. If the material you would like to compare is not available in the list, you can input the relevant mechanical properties manually.

In piston rod predictor, you can decide to use the diameter of an existing rod as the input to calculate what diameter would be required with an alternative steel grade to achieve the same safety factor. Alternatively, you can use your maximum load and desired safety factor to calculate the minimum rod diameter for different steel grades.

The output is given in exact numbers and will therefore need to be rounded up to match available/desired rod diameters. The effective length must also be calculated from your specific load case and method.

The methods used to calculate the buckling stress are the European Convention for Constructional Steelwork (ECCS) procedure and the American Institute of Steel Construction (AISC) procedure. These are two of the most common methods for calculating buckling. Out of these two methods, the AISC is slightly more conservative, but the results are similar and have been shown to be close to reality in empirical tests.

Effective length must be calculated from the actual load case. A method of calculating the effective length for common hydraulic cylinder load cases is to use the cases described in EN13001-3-6-Hydraulic cylinder for cranes Annex A.

For more information or questions, please contact us on info.cromax@ovako.com

Disclaimer: The results from the calculations are for guidance and not guaranteed to be accurate. Continuous development of the guide is made to improve the calculation results.