General Information

100Cr6 is a through hardening bearing steels intended for rolling contact and other high fatigue applications. In the hardened condition the high hardness, high strength and high cleanliness provides the steel with the right properties to withstand high cycle, high stress fatigue. 100Cr6 is mainly used for small and medium sized bearing components. It is also regularly used for other machine components that require high tensile strength and high hardness. The hardenability approximately corresponds to a ring with max. 17 mm wall thickness.

This steel is delivered in a number of variants. The most common are listed below.

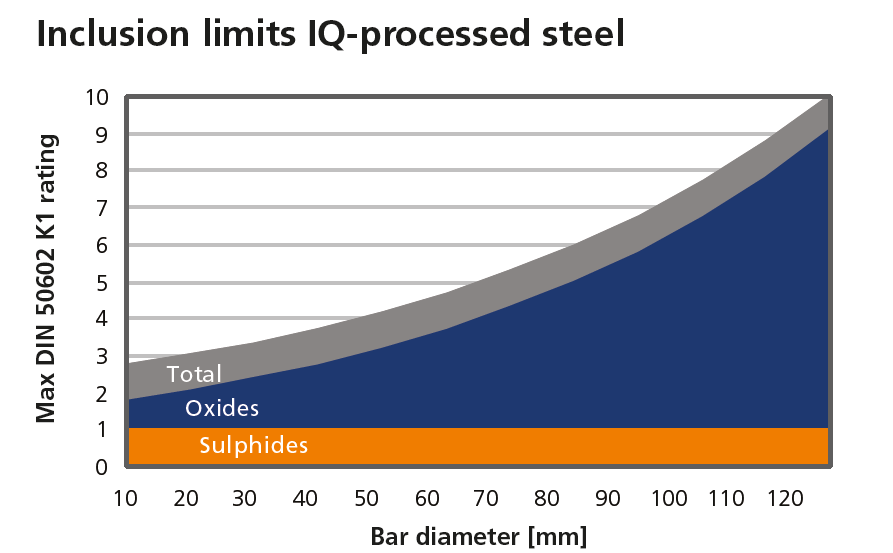

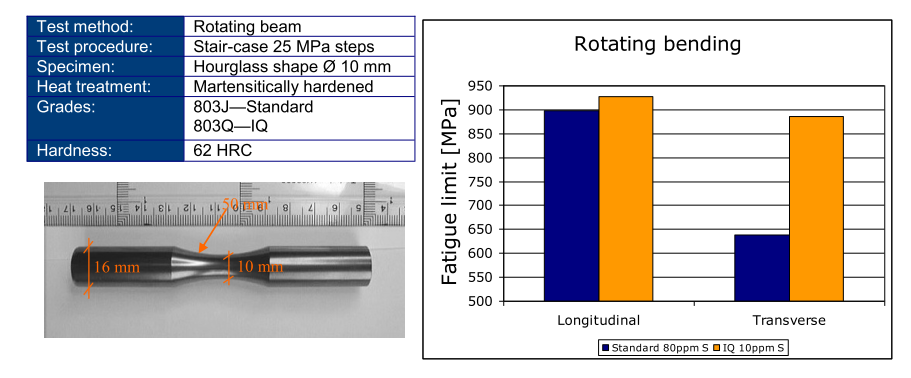

803Q - Isotropic properties and better fatigue strength due to higher cleanliness levels, and a finer size and distribution of non-metallic inclusions (IQ)

803Z - Improved cold forming properties due to the reduced silicon content (BQ)

803D - Improved machinability due to the higher sulphur content.

803P - With a reduced sulphur content to reduce the number of sulphide inclusions (BQ)

803A - With a reduced controlled sulphur content to reduce the number of sulphide inclusions but ensure consistent machinability (BQ)

803F - With a controlled sulphur content for consistent machining properties (BQ)

803N - Slightly increased carbon range to meet the requirements of some international standards (BQ)

803J - Standard (BQ)

5620 / 802F - A continuous cast variant of 100Cr6 (BQ)

BQ-Steel®

BQ-Steel® is a bearing quality clean steel optimized for fatigue strength and is also ideal for new design solutions outside the bearing industry.

Similar designations

SS 2258, SAE 52100, 1.3505 , 100 Cr 6 , SUJ2S, SUJ2Z, 100C6, GCr15, B00150